Structural Tubing

Structural tubing per ASTM A500 is tubing produced and used for structural applications. Standard strength requirements of the tube help dictate applications for which certain tubing is most appropriate. Structural tube is often referred to as hollow structural sections or HSS. Structural Tubing, especially rectangular sections, is commonly used in welded steel frames where members experience loading in multiple directions. Square and circular HSS are very efficient shapes for this multiple-axis loading as they have uniform geometry along two or more cross-sectional axes, and thus uniform strength characteristics. This makes them good choices for columns. They also have excellent resistance to torsion. The flat square surfaces of HSS structural tubing can ease construction, and they are sometimes preferred for architectural aesthetics in exposed structures. HSS structural tubing is most commonly produced to ASTM A500 grade B standards, but can also be available in ASTM A1085 as well. Structural products are ordered to a specific outside dimension (OD) and “gauge” or wall thickness.

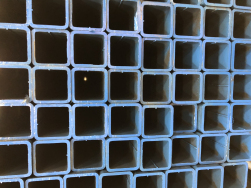

Stocked Size Range and Shapes

- Square: 0.500" to 16.000" with 0.065" to 0.625" Wall Thickness

- Rectangle: 1.000" x 0.500" to 20.000" x 12.000" with 0.065" to 0.625" Wall Thickness

- Round: 0.750" to 20.000" O.D. with 0.065" to 0.625" Wall Thickness

Structural Tubing Manufacturing Process

ASTM A500 structural tubing is welded tubing made from flat-rolled steel, formed through a roller system and welded using electric-resistance welding. Longitudinal butt joints of welded tubing shall be welded across its thickness in such a manner as to assure the structural design strength of the tubing section. Welded structural steel tubing is normally furnished without the removal of inside flash.

Benefits of Structural Tubing

Strength

HSS has a high strength-to-weight ratio, excellent compression support characteristics, and excellent torsional resistance. A500 structural tubing has excellent structural integrity and load-bearing capacity, with the ability to withstand heavy loads and provide longevity.

Compliance with Standards

Structural tubing complies with industry standards and specifications, ensuring that it meets safety and performance requirements.

Uniformity

HSS provides uniformity of size, shape, strength and tolerances that make its use totally predictable, especially important for demanding OEM applications.

Ease of Fabrication

HSS can be readily bent, formed, punched and drilled. Improvements in connection design for fastening HSS to itself or other structural materials are improving the ease of fabrication in the field as well.

Durability

A500 Structural Steel tubing is designed to withstand harsh environmental conditions, with exposure to extreme temperatures, moisture, and corrosive elements.

Cost Effectiveness

Due to its higher strength ratio, especially in A1085, HSS is cost-competitive with other structural materials. With improved connection and fastening methods, it often enjoys a cost advantage, due to its long life-span and low maintenance.

Resistance

HSS is fire resistant and does not warp, twist, split, swell or shrink.

Consistency

It resists dry rot and mildew.

Recyclability

Stainless steel is highly recyclable, so HSS reduces its environmental impact and contributes to the sustainability initiative.

Range of Applications

Structural tubing is used in a variety of applications, including the construction of buildings, bridges, infrastructure, and industrial machinery. Structural tubing can perform well for both simple and complex projects.

Aesthetic Appeal

When some projects and applications may require visible structural elements, structural tubing can provide a modern look and feel to the overall appearance of a building or structure. In exposed applications, especially Architecturally Exposed Structural Steel (AESS) applications in construction, HSS provides preferred visual opportunities for the design of buildings and other structures.

Applications by Industry

Construction & Heavy Equipment

- Cranes, Frames, Roll-Over Protective Structures (ROPS), Numerous Types of Construction Equipment – Bulldozers, Excavators, Steam Rollers, etc.

Agriculture

- Cranes, Frames, Roll-Over Protective Structures (ROPS), Numerous Types of Agricultural Equipment – Combines, Sprayers, Harvesters, Tractors, etc., Greenhouse Structures

Infrastructure

- Columns, Bridges, Buildings, Towers, Signs, Awnings

Fluid Handling

- Pump Bases, Hydraulic Brackets, Spacers

Machinery

- Machine Bases, Machine Frames

Oil & Gas

- Off-Shore Drilling Platforms, Off-Shore Production Equipment, Tooling Racks

Energy

- Solar Brackets and Bases, Solar Racking, Power Plants

General Fabrication and Machining

- Racks, Spacers, Bases, Numerous other general welding and machined applications

Automotive & Transportation

- Auto & Truck Frames, Trailers Truck Bases, Rail Cars, Automotive Racks, Carports

Industrial Tube & Steel Corporation stocks carbon steel square tubing in A513 (mechanical) and A500 (structural) grades, in a range of sizes and wall thicknesses.

View All

Industrial Tube & Steel Corporation stocks carbon steel rectangular tubing in A513 (mechanical) and A500 (structural) grades, in a range of sizes and wall thicknesses.

View All

Industrial Tube & Steel Corporation stocks carbon steel round tubing in A513 (mechanical) and A500 (structural) grades, in a range of sizes and wall thicknesses.

View All