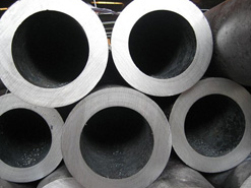

Hot Rolled Seamless Tubing

As a supplier and distributor of metal tubing for over 65 years, Industrial Tube and Steel Corporation provides a variety of Hot rolled seamless (HRS) tubes (also known as HFS or Hot finished seamless), a lower-cost product than CDS tube and is a good material for applications that do not require the close dimensional tolerances and quality of surface finish that CDS tube provides. If tight tolerances are required, machining is used to finish the product to the exact specifications. Hot-finished seamless tubing is easy to machine to meet any requirements. HRS is used for products that require a thicker wall and a high-strength material.

Made from 1026 Steel

Meets ASTM A519 (Hot Finished)

A519 HRS Tubing Tolerances

Stocked Size Range

- 3.000" to 26.000" O.D. with 0.438" to 4.000" Wall Thickness

- Stocked in 17.000’ - 24.000’ random lengths (cut to length available)

Manufacturing Process of Hot Rolled Seamless (HRS) Tubing:

Hot-rolled mechanical tubing is produced by heating a solid billet or bar and then rotary piercing it as it rotates on rollers. Then the final processing through multiple pass size-reducing mills occurs. Tolerances and finish are similar to other hot-worked steel products. The range of sizes and grades is more restricted than cold finished by the nature of the process involved. This tubing is used where dimensional accuracy and surface finish are unimportant or secondary, or where desired tolerances, finish, and final mechanical properties are to be attained by machining and heat treatment. HRS tubing is manufactured to the outside diameter (OD) and wall thickness (W) dimensions.

Benefits of Hot Rolled Seamless (HRS) Tubing:

Cost-Effectiveness

- HRS is a great alternative to bar with a hole being machined into it. Reduced machining time reduces overall part cost.

Versatility

- HRS is an excellent candidate for most processing techniques and allows for many options due to its available sizes produced.

Machinability

- HRS is easily machined, with a minimal stock allowance for clean-up. It has excellent machining characteristics and is mild carbon.

Wide Range of Sizes

- HRS can be manufactured to a large range of OD and wall thickness dimensions due to it being rolled bar and pierced.

Machining – Hot Rolled Seamless (HRS) Tubing:

Determining the proper tube size is essential when producing a machined part from seamless mechanical tubing. To calculate the tube size needed to machine a given part, several important points should be considered:

- The finished machined part size—OD, ID, length, and tolerances.

- Have the raw material tolerances per ASTM A519 been factored in?

- The machining sequence, type of machining, and processing.

- Will the tubing be machined true to the OD or ID?

- Will the OD or ID be machined?

- Will heat treating be used, and at what point in the production process?

- How will it be held or chucked?

Applications By Industry:

Construction & Heavy Equipment

- Hydraulic Cylinders

- Drilling Equipment

- Bushings

- Spacers

- Axles

- Bearings

- Deforestation Equipment

Agriculture

- Hydraulic Cylinders

- Augers

- Booms

- Shafts

- Spacers

- Bushings

- Axles

- Bearings

Infrastructure

- Rollers

- Lift Components

- Bases

- Large Columns

Fluid Handling

- Pumps

- Other Components Which Liquids Will Flow (Especially at High Speeds)

- Sleeves

- Flanges

- Swivels

Machinery

- Numerous Internal Machine Components

- Pumps

- Frames

- Wheels

- Industrial Lift Components

- Cylinders

- Rollers

- Tool Extensions

Oil & Gas

- Pumps

- Barrels

- Cylinders

- Drilling Components

- Augers

- Plungers

- Bearing Races

- Spacers

Energy

- Swivels

- Waste Treatment

- Wind Turbine Components

- Nuclear, Wind, Solar, Gas, and Coal Plant Applications

General Fabrication and Machining

- Size Specific Needs

- Supports

- Machined Parts

- Paper, Textile & Steel Mill Rolls

Automotive & Transportation

- Auto & Truck Axles

- Auto Engine Assemblies

- Sleeves

- Chassis

- Dampeners

- Pillars

- Shafts (Drive, Half and Prop)

- Brackets

Streamline your supply chain with high-quality Hot Rolled Seamless Tubing (HRS) from Industrial Tube & Steel. As a leading metals distributor for over 65 years, we have the inventory, resources, and capabilities to meet your material needs on time and within budget.

Contact us for more information.

Customized Cut Lengths Available. Please Specify Cut Length During Quote Process.

Hot Rolled & Finished Seamless Tubing (HRS) Supplier

For more information and quick references pertaining to raw material, machining, heat treating, and I.T.S. offerings, click here.

View All

Use our calculators to help determine the weight or dimension of your specific raw material needs.

View All