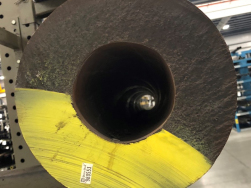

Ductile Iron Trepanned Tubes

Industrial Tube & Steel’s ductile continuous cast iron tubes are typically stocked in 65-45-12 grade. When requested, other ductile iron grades such as 80-55-06, 100-70-03, and SSDI can also be trepanned depending on available diameters. Let Industrial Tube & Steel Corporation help you minimize time and cut cost by supplying you with a trepanned ductile iron tube versus bar.

Ductile Iron Tube Basics

Ductile iron tubing is a sturdy, high-performing and versatile material with a lower overall cost than comparable carbon steels. Continuous cast ductile iron is easy to machine and has the following characteristics:

- Superior corrosion resistance

- Excellent fatigue strength

- Superior machinability

- Fine-grained surface finish

- Heightened wear resistance

- High thermal conductivity

Ductile iron trepanned tubes are stocked in many sizes, from 3.500” O.D. x 1.500” I.D. to 9.000” O.D. x 7.000” I.D. range. The concentricity tolerance between the I.D. and O.D. is 0.250". Stock length is 72” but can be produced in longer lengths upon request. See Dura-Bar Iron Stock Allowance for more information.

With our skilled employees and industry-leading equipment, we can supply your raw material needs cut to your specified dimensions quickly and efficiently.

Ductile Iron Tube Types

Industrial Tube & Steel carries a vast inventory of ductile continuous cast iron tubing to suit any purpose. This material is produced to meet ASTM A536 specification standards, stocked in 65-45-12 grade, and can be available in any of the following grades:

- 65-45-12

- 80-55-06

- 100-70-03

- Solution Strengthened Ductile Iron, or SSDI

65-45-12 grade ductile iron contains nodular graphite in a matrix of ferrite with small amounts of pearlite. The ferritic structure gives excellent machinability with good surface finishes along with optimal impact strengths, fatigue properties, electrical conductivity, and high magnetic permeability. This iron has approximately the same tensile and yield strengths as AISI 1020 steel in the as-rolled condition.

80-55-06 grade ductile iron contains nodular graphite in a matrix of ferrite and pearlite. The pearlite-and-ferrite structure provides higher wear resistance and strength when compared to a ferritic grade of ductile iron. This material is readily machinable and displays good surface finishes. Tensile and yield strengths are similar to AISI 1040 steel in the as-rolled condition.

100-70-03 ductile iron combines nodular graphite in a matrix of pearlite with a small amount of ferrite. It's produced in a range of sizes and shapes and is often used in place of plain carbon steel. Its machinability is similar to carbon steel.

SSDI (Solution Strengthened Ductile Iron) is a grade of ductile iron that combines the high mechanical strengths of a pearlitic ductile iron with the machinability advantages of a ferritic ductile iron. It’s an attractive grade of ductile iron for the design and manufacture of metal components.

Ductile Iron Tube Applications

While ductile iron tubing exhibits toughness that’s comparable to low-to-medium plain carbon steels, it’s also a more cost-effective option. Ductile iron trepanned tube is an excellent material for many industries, which include:

As a leading metals distributor, Industrial Tube & Steel has the inventory, resources, and capabilities to supply high-quality material on time and within budget. Contact us today to learn more!

Customized Cut Lengths Available. Please Specify Cut Length During Quote Process.

Ductile Continuous Cast Iron Tube

For more information and quick references pertaining to raw material, machining, heat treating, and I.T.S. offerings, click here.

View All

Use our calculators to help determine the weight or dimension of your specific raw material needs.

View All