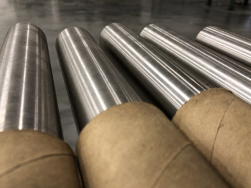

303 Stainless TG&P

303 Stainless Turned, Ground & Polished Precision Shafting is a non-magnetic, austenitic stainless steel that is not able to be hardened by heat treatment. It is the free machining modification of the basic 18% chromium / 8% nickel stainless steel. Alloy 303 was specially designed to exhibit improved machinability while maintaining good mechanical and corrosion-resistant properties. Due to the presence of sulfur in the steel composition, Alloy 303 is the most readily machinable austenitic stainless steel; however, the sulfur addition does lower Alloy 303’s corrosion resistance to below that of Alloy 304. Like other austenitic grades, Alloy 303 demonstrates excellent toughness, although the sulfur does reduce this a little as well.

Meets ASTM A582

TG&P Bar Diameter Tolerances

Benefits of 303 TG&P Shafting

- Corrosion resistant to harsh atmospheric elements

- Excellent machinability for precise shapes and sizes

- Precision machining applications include the chemical and aerospace industries

- High-quality finish

- High-strength

| Mechanical Properties (Typical Min.) | |

|---|---|

| Tensile Strength (PSI)* | 85,000 PSI |

| Yield Strength | 45,000 PSI |

| Elongation | 50% |

| Chemical Composition | |

|---|---|

| Element | Percentage (%) |

| Carbon | .15% max |

| Chrome | 17.0%- 19.0% |

| Manganese | 2.0% max |

| Nickel | 8.0% -10.0% |

| Phosphorus | 0.20% max |

| Sulphur | .15% min |

| Silicon | 1.00% max |

Customized Cut Lengths Available. Please Specify Cut Length During Quote Process.

303 Stainless Steel TG&P Shafting

For more information and quick references pertaining to raw material, machining, heat treating, and I.T.S. offerings, click here.

View All

Use our calculators to help determine the weight or dimension of your specific raw material needs.

View All